Mergen-Smart Factory R&D Project

1-Mergen development history

2-Positive Impact of Smart Factory on Cost of Quality

3-Steel structure manufacturing process

4-Required Certificate for Steel structure manufacturer companies

5-Planning and management systems

6-Required documents for Certificate of conformance

7-Management systems targeted with Mergen

8-Mergen is a ERP Software

9-Mergen is a MIS Software

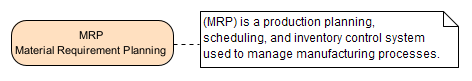

10-Mergen is a MRP Software

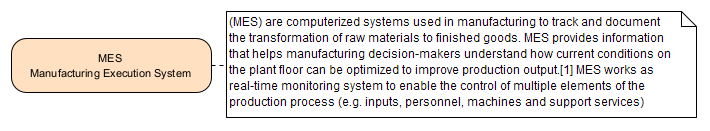

11-Mergen is a MES Software

12-Mergen is an Occupational Safety and Health Management Software

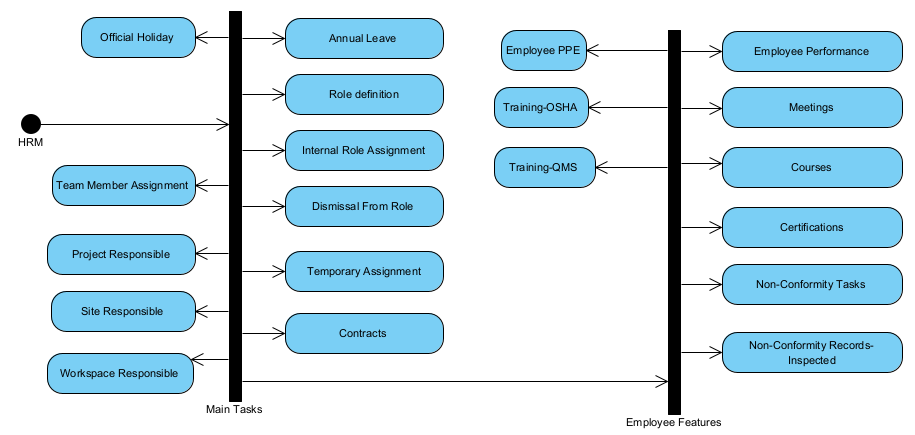

13-Mergen is a HRM Software

1-Mergen development history

Mergen is a process tracking and decision support software development project for steel structure manufacturing factories. This R&D project was supported by The Scientific and Technological Research Council of Turkey (TUBITAK) for 42 months between 2018-2021. The project budget is $454,000 in 2018. As of 2025, taking into account US inflation, the current cost is $642,000.

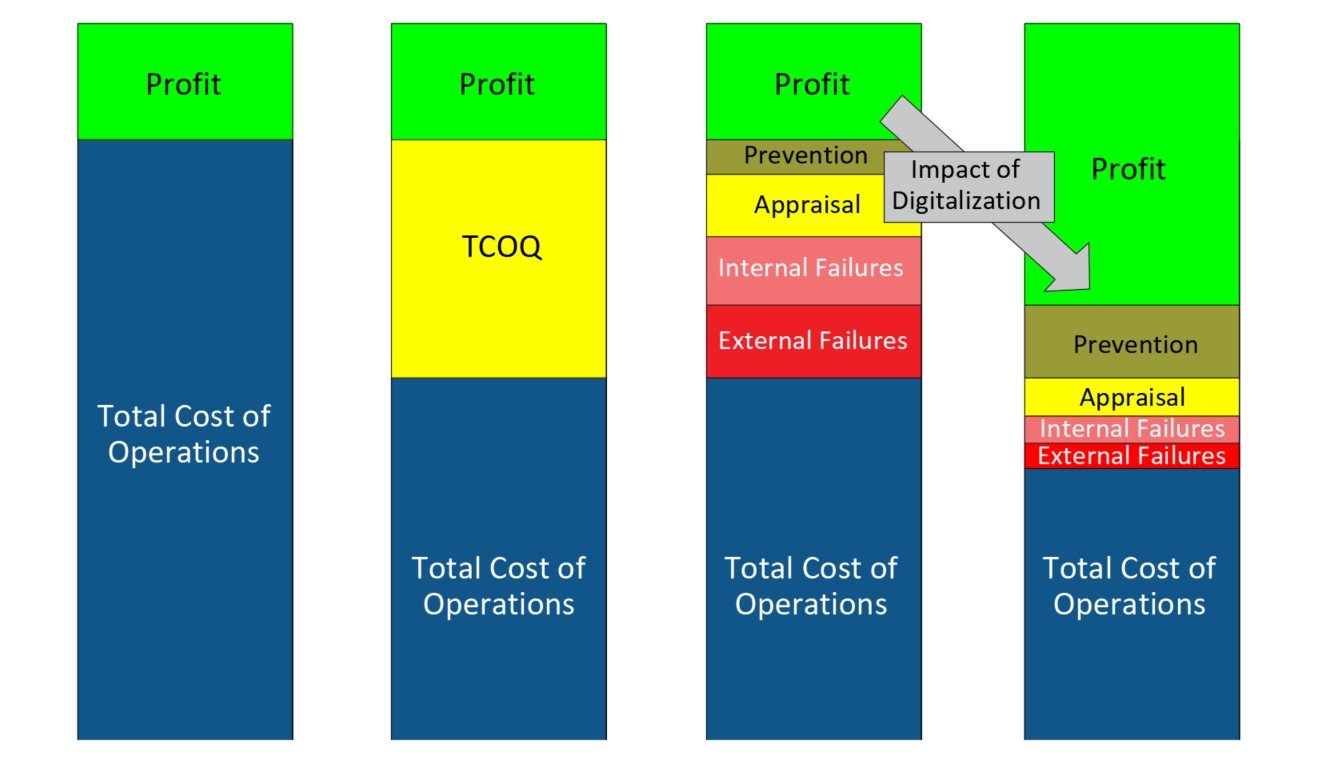

2-Positive Impact of Smart Factory on Cost of Quality

In a factory at Industry 3.0 level, the profit is 20% as in the 1st column and the total cost of the work done is 80%. As seen in column 2, around 35% of the total cost is spent to make quality production. In column 3, 20% of the 35% quality production cost is internal and external errors. 10% is the cost of evaluating quality and 5% is the cost of trying to prevent errors.

One of the new concepts that comes with Industry 4.0 is Quality 4.0. In the 4th column, thanks to digitalization, real-time quality control reduces the cost of evaluation and non-conformities while slightly increasing the cost of prevention. As a result, better quality manufacturing can be done 25% cheaper.

In the Mergen R&D project, digital transformation is aimed in a field with complex production processes in steel structure manufacturing. The fabrication is carried out using technical drawings and DSTV-NC files obtained from the 3D model (IFC) of the steel structure thanks to Building Information Modelling (BIM).

In this project, steel structure manufacturing will be carried out using IFC and DSTV-NC files and production stages will be monitored via 3D model (IFC).

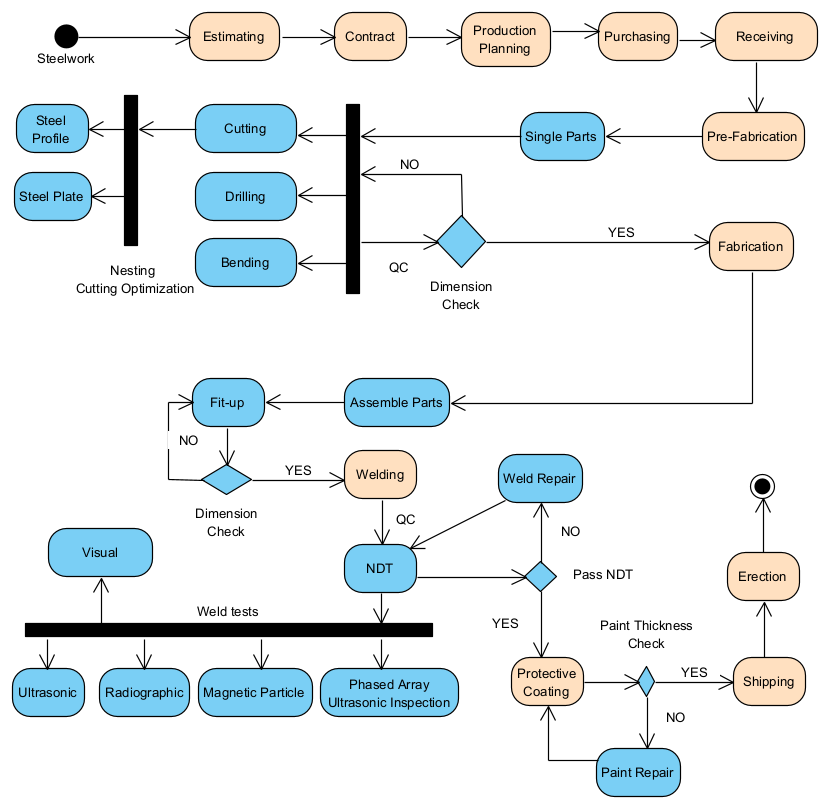

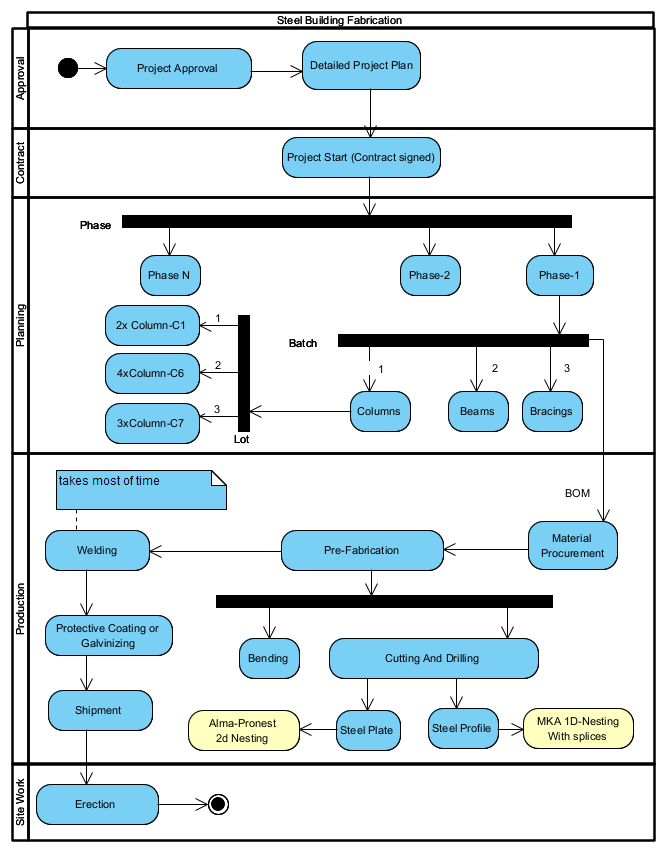

3-Steel structure manufacturing process

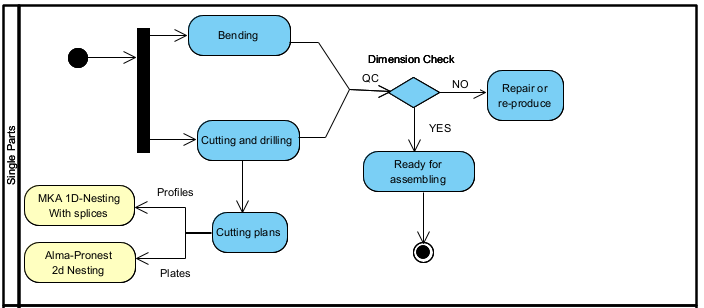

Let’s start by explaining our project, the manufacturing processes of a steel structure, when the flow diagram below is examined

It looks like a structure that can be applied to many factories. Since the steel structure is made once, the type of production in this factory is discontinuous. Since it is customized, it makes it difficult to develop a software project to follow the process due to change requests in the middle of production.

When we came to the end of the project with about 4 years of work (2022), we realized that the software had to be connected to a quality management system. We saw that each factory had a different quality management system. For this reason, instead of including Mergen in their own systems, factories started to request their own systems in Mergen.

In the meantime, we purchased the manuals required for the Certificate, which is compulsory for steel structure manufacturers, whose rules, called AISC Certificate in the USA, are in the AISC-207-16 standard. It was a complete quality management system for steel structure manufacturers.

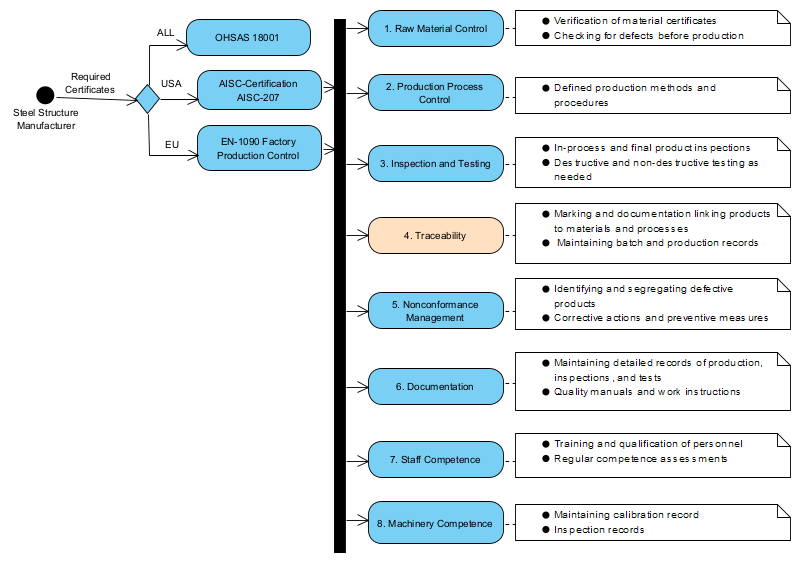

4-Required Certificate for Steel structure manufacturer companies

In this direction, we continued to develop Mergen. In order to understand the subject, let’s briefly examine the certificates required for the steel structure manufacturing factory targeted with Mergen.

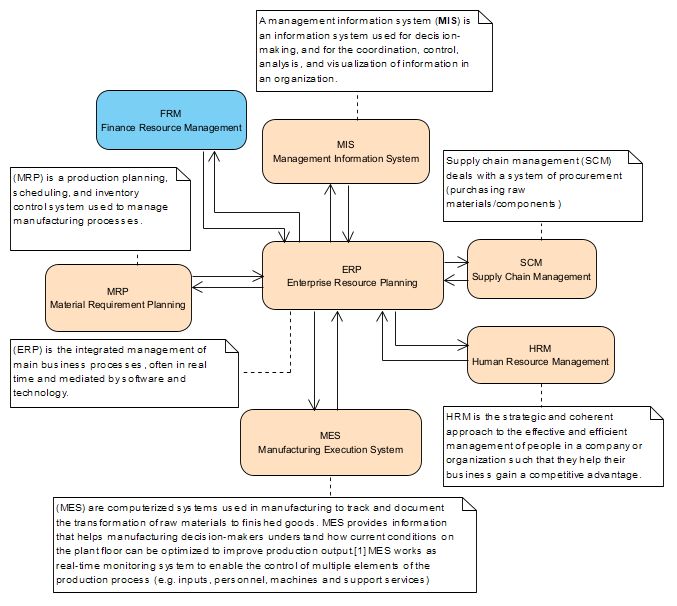

5-Planning and management systems

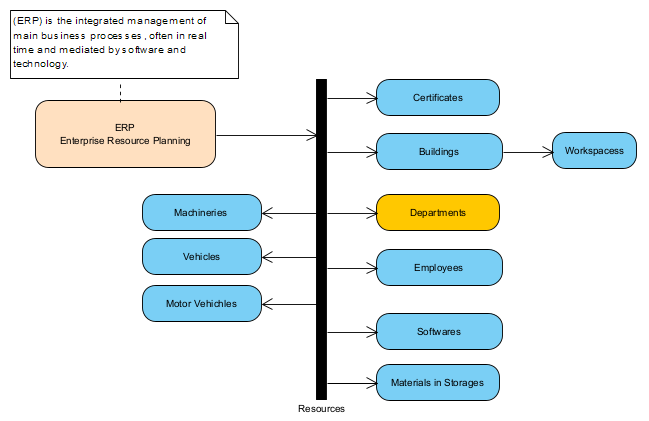

Nowadays, management and planning systems used in industry such as ERP, MRP, MES, MIS, CRP, FRP are widely used. For example, integrating an ERP system to mass production factory takes more than a year. In factories with discontinuous production, this period can be significantly longer.

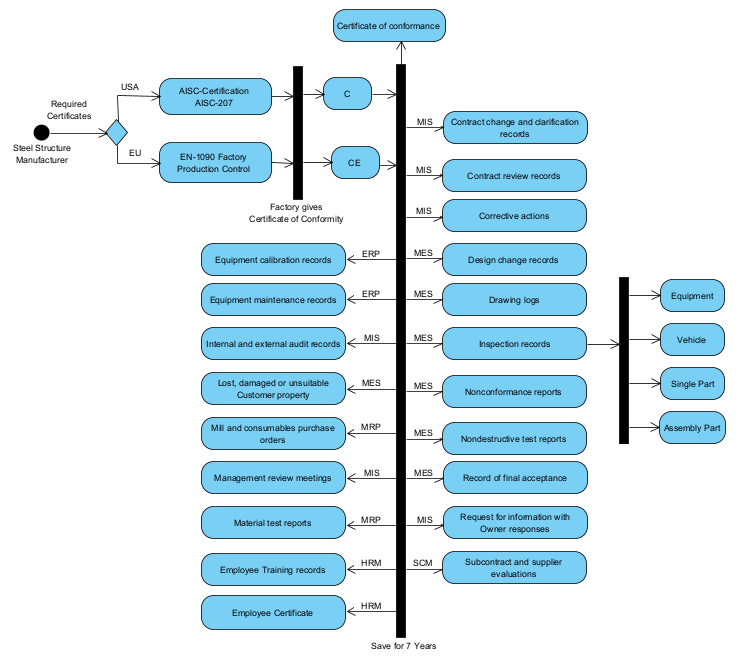

6-Required documents for Certificate of conformance

The steel structure manufacturing company must certify that it meets the necessary quality requirements when delivering the final product to the customer. For this purpose, the factory must have AISC Certification in the USA and EN-1090 Factory Production Control Certification in the EU.

The biggest problem for the manufacturer is the multiplicity of documents that must be provided when issuing the “Certificate of Conformance” to the customer. Although a company that manufactures 100 tons of steel structures per month can produce these documents using MS-Word MS-Excel, this is a huge task for a company that makes 1000 tons per month.

When the above diagram is analyzed, it is concluded that many management and planning systems should be used together

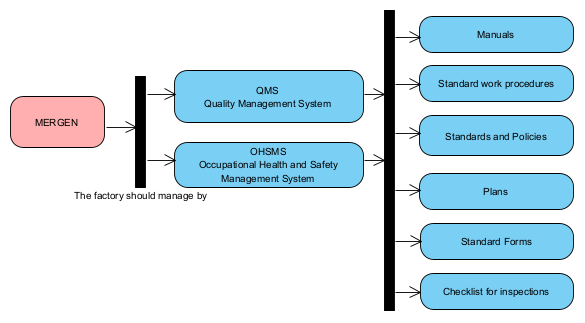

7-Management systems targeted with Mergen

Accordingly, we realized that Mergen should not only be a factory production software. We have developed it, to be

- a MIS software that shows to the management what is going on in the factory,

- a MES software that enables real-time detection of problems in production,

- and an ERP software that can be used for resource planning for the structure to be produced.

While doing this, we tried to adhere to the management systems that related to Quality / Occupational Health and Safety, so that the transition period of the factory to Mergen would be very short.

8-Mergen is a ERP Software

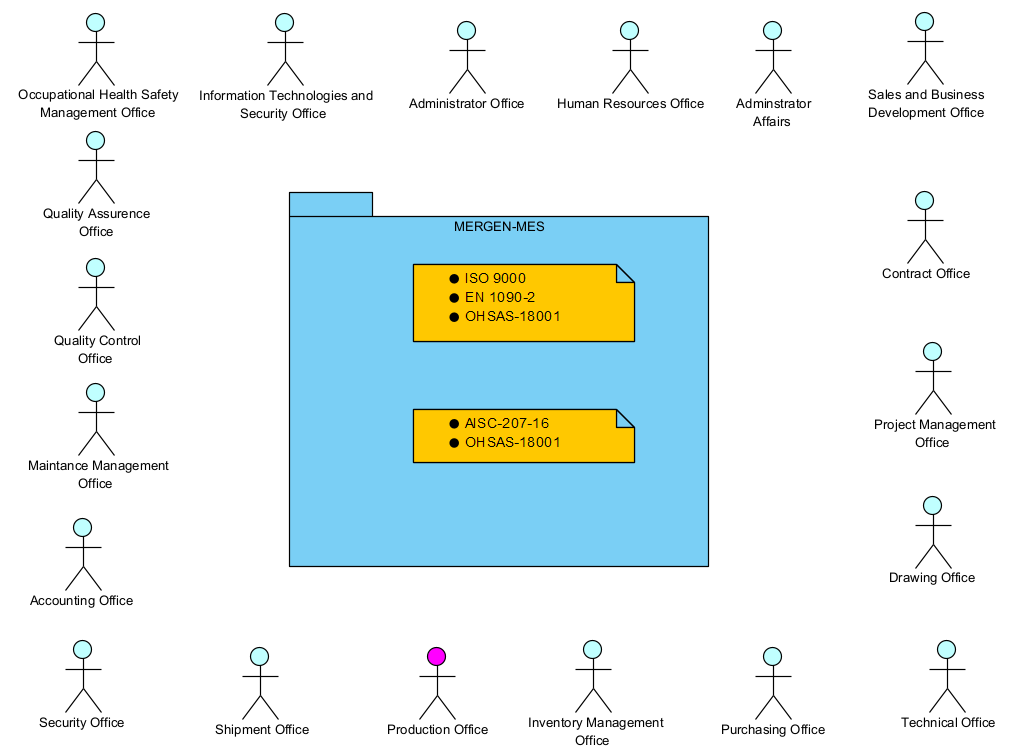

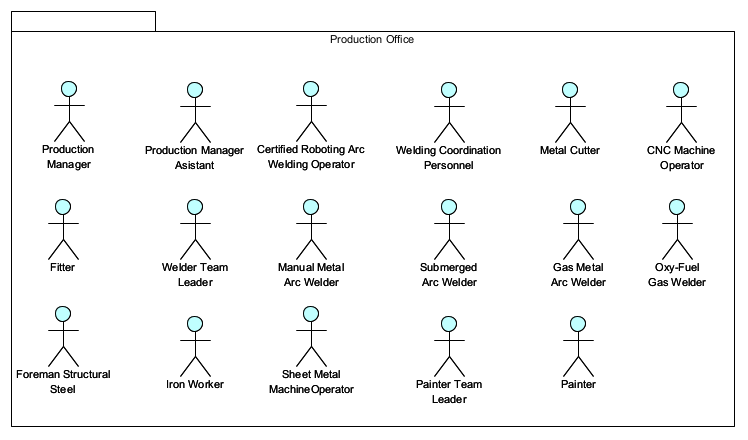

In a steel structure manufacturing factory, there are mainly the above departments. In Mergen, there is a separate module for each department. Let’s take the Production Office as an example.

The roles of the people in this office are given above. Role holders who have the authorization to use the relevant module in Mergen can access it. The operations they can do according to each role are limited.

9-Mergen is a MIS Software

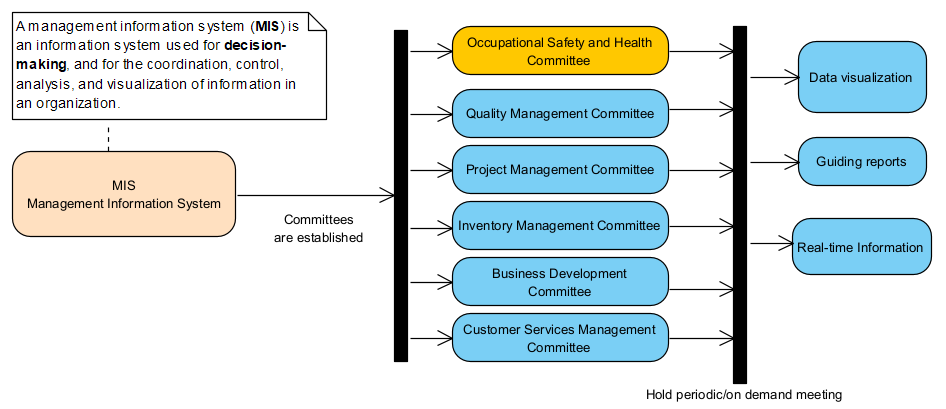

Since all departments within the factory use the same system and database, information is collected in one place. By using this data accumulated over time, information can be obtained to improve the efficiency of the factory.

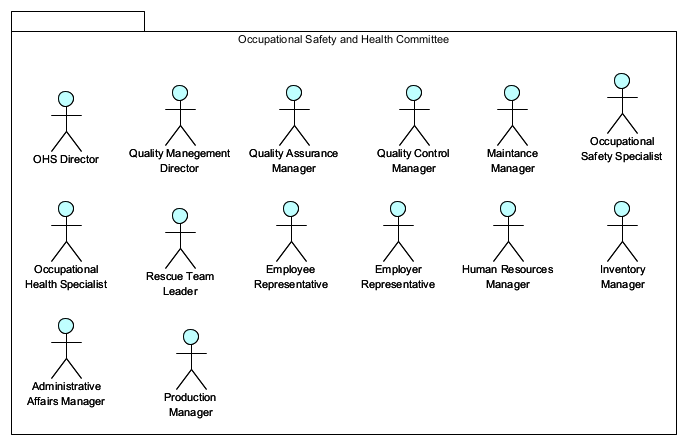

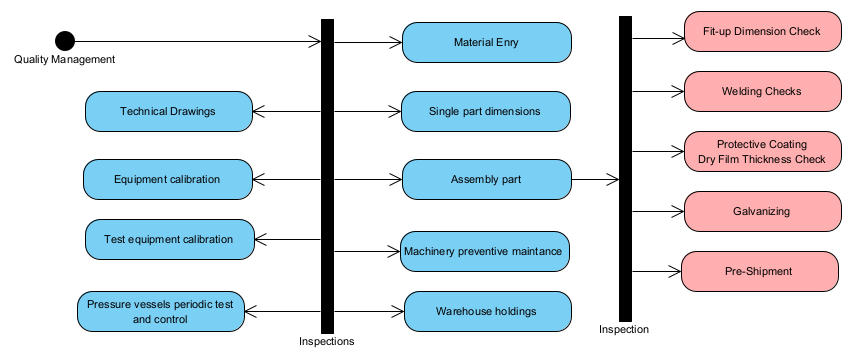

The Quality Management System (QMS) and Occupational Health and Safety Management System (OHSMS) require the establishment of several committees and periodic meetings of these committees.

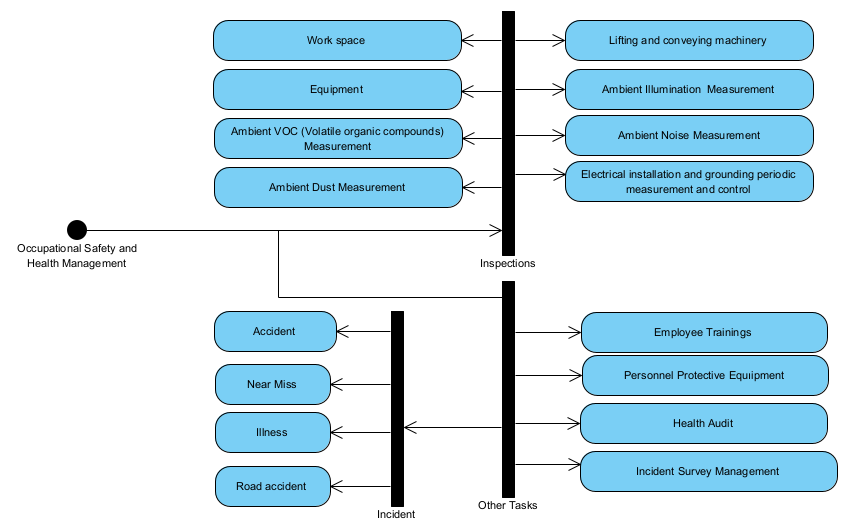

In these meetings, the data accumulated in the Mergen database can be used for data visualization, guiding reports and real-time tables. This information is intended to be tailor-made for the meeting. Let’s take the Occupational Safety and Health Committee as an example here

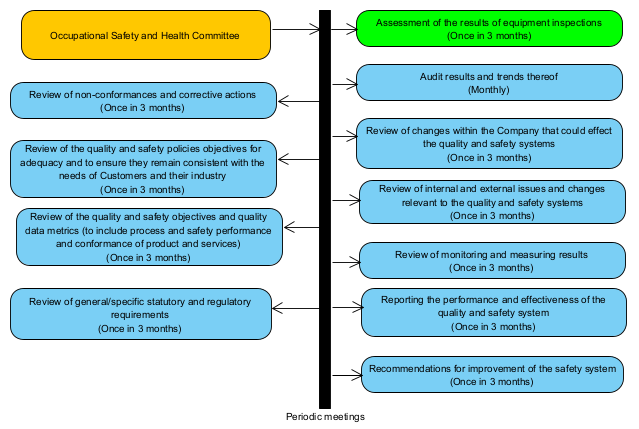

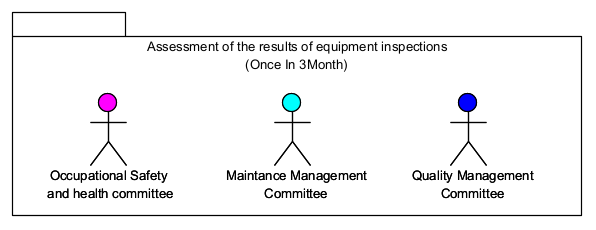

The diagram above shows the periodic meetings that the Occupational Safety and Health Committee should hold. Take the meeting “Assessment of the results of equipment inspections”. This meeting is held by more than one committee.

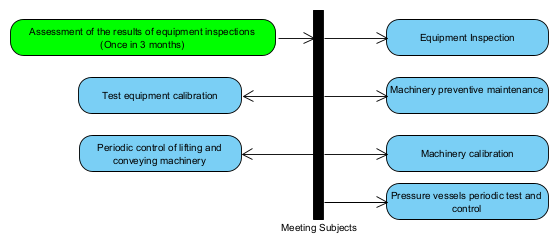

The topics given in the diagram below will be discussed at the meeting. Mergen’s goal is to visualize the information about the meeting topic using the data in the database to guide the management and save time.

Today, most of this information is in MS-Excel sheets. Analyzing the data and preparing meaningful reports is labor intensive and depends on the competence of the preparer.

10-Mergen is a MRP Software

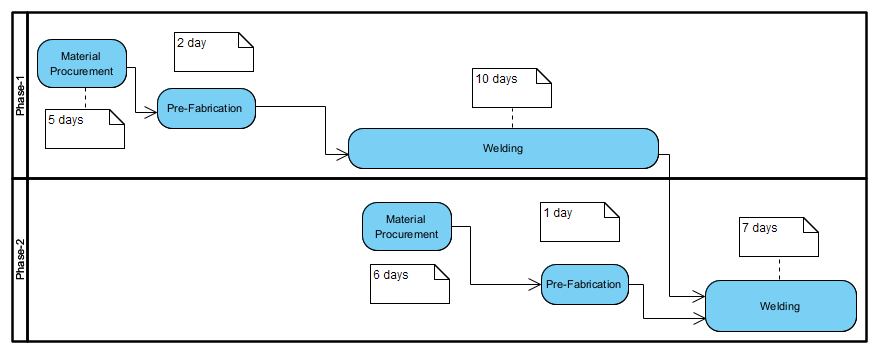

Manufacturing stages are given in the diagram below. In the planning phase, the project is divided into parts such as phase, batch and lot by considering the erection order.

In the production phase, the time required for material procurement varies according to the supplier. The pre-production stage is usually quite fast because CNC machines are used. However, the welding stage is time consuming. The type of welding, quantity, number of welders, competence of welders determine the duration of this stage.

When the above diagram is analyzed, the welding phases of the project is completed in (5+2+10+7=24) days. The materials of phase2 should be supplied 7 days before the end of the Phase1 welding stage. In other words, the materials of Phase2 should be ordered 10 days after the start of the project at the latest.

The above plan may show deviations due to many reasons such as delay in material supply, incorrect estimation of welding quantity, detected weld defects during quality control, absenteeism of welders.

It is important to create the production plan. However, it is much more important that the plan be followed in real time. Therefore, Mergen should also be a MES software.

11-Mergen is a MES Software

The roles of the people in this office are given above. Role holders who have the authorization to use the relevant module in Mergen can access it. The operations they can do according to each role are limited.

For single parts

Steel plates and profiles are cut and processing according to special cutting plans. This is an attempt to minimize waste. After this process, measurement control is performed to check the calibration of the CNC machine. Before the fit-up stage, the part numbers are written on or the individual part barcode is affixed.

By digitally monitoring this process, it is possible to know which assembly parts are ready for the fit-up stage.

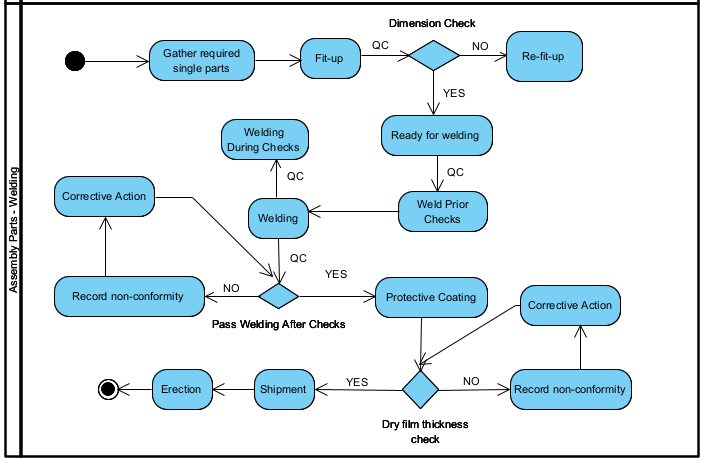

For assembly parts

Fit-up and welding are the most critical stages. In the fit-up stage, the individual parts to be welded on the assembly part are spot welded for dimensional control. For the CE certificate to be delivered to the customer, a record showing that this control has been carried out is required.

There are controls to be carried out before, during and after the welding stage. Records of these controls will be delivered to the customer. If weld defect is detected at the source, a record of this will be kept. Thus, the defective assembly part and the welder who made this error can be followed.

12-Mergen is an Occupational Safety and Health Management Software

Occupational Safety and Health Management and quality management systems are similar to each other in many respects.

In order to be able to issue a Certificate of Conformity, the quality management system is required to carry out the above-mentioned audits and to keep the records and to keep them for 7 years.

Standardized checklists are needed to obtain meaningful data after these audits.

When the standardized checklist method used in audits related to quality management is used for occupational health and safety management, it is possible to monitor the hazard and risk status of the factory in real time.

13-Mergen is a HRM Software